What is PLC Tool Software?

Explore the pivotal role of PLC Tool Software in industrial automation. This post delves into PLCs definition, significance, key features, and future trends, helping you harness its full potential to drive efficiency and innovation in your automation projects.

In industrial automation, PLC Tool Software plays a pivotal role in streamlining processes and enhancing efficiency. This blog post delves into the intricacies of PLC Tool Software, exploring its definition, significance, functions, and future trends.

Definition of PLC Tool Software

PLC Tool Software refers to specialized programs designed to program, monitor, and control Programmable Logic Controllers (PLCs) in industrial settings. These software tools are essential for configuring automation processes and ensuring seamless operation of machinery.

Importance of PLC Tool Software in Industrial Automation

Using PLC Tool Software is crucial for optimizing industrial processes, improving productivity, and enabling real-time monitoring and control of equipment.

Its significance lies in its ability to automate tasks, reduce human intervention, and enhance operational efficiency.

Understanding PLCs

Overview of Programmable Logic Controllers (PLCs)

PLCs are electronic devices used to control various industrial applications by executing specific tasks based on programmed logic. They serve as the brains of automation systems, interpreting inputs and generating outputs to facilitate seamless operation.

Functions and Applications of PLCs

PLCs are versatile tools employed in a myriad of industries for tasks such as process control, data acquisition, and machinery automation. Their applications range from simple relay replacement to complex control systems in manufacturing plants, utilities, and automotive industries.

Evolution of PLC Tool Software

Historical Background of PLC Tool Software

The evolution of PLC Tool Software traces back to the development of PLCs in the late 1960s. Initially, programming was done through physical wiring, but with technological advancements, software-based programming tools emerged, revolutionizing industrial automation.

Advancements in PLC Programming Tools

Modern PLC Tool Software offers advanced features like graphical programming interfaces, simulation capabilities, and seamless integration with other automation systems. These tools have evolved to meet the increasing demands of complex industrial processes.

Features of PLC Tool Software

Programming Capabilities

PLC Tool Software enables users to create logic programs, configure input/output devices, and customize control algorithms to suit specific automation requirements.

The intuitive interfaces simplify programming tasks, making it accessible to both novice and experienced users.

Simulation and Testing Functions

One of the key features of PLC Tool Software is its simulation and testing capabilities.

Users can validate their logic programs virtually, identify errors, and fine-tune control strategies before deploying them in real-world scenarios. Thus, reducing downtime and enhancing system reliability.

Compatibility with Different PLC Brands

Modern PLC Tool Software is designed to be compatible with a wide range of PLC brands, ensuring interoperability and flexibility in automation projects.

This compatibility allows users to work with diverse PLC platforms without facing compatibility issues.

Benefits of Using PLC Tool Software

Increased Efficiency in Programming

By providing a user-friendly interface and powerful programming tools, PLC Tool Software streamlines the development process, reducing programming time and enhancing overall efficiency in automation projects.

Enhanced Troubleshooting Capabilities

PLC Tool Software offers various diagnostic tools and real-time monitoring features. These features facilitate quick identification of faults, troubleshooting of issues, and efficient maintenance of industrial systems, minimizing downtime and optimizing productivity.

Cost-Effectiveness in Automation Projects

The use of PLC Tool Software results in cost savings by improving operational efficiency, reducing manual labour, and minimizing errors in programming and control. This cost-effectiveness makes PLC Tool Software a valuable investment for industrial automation.

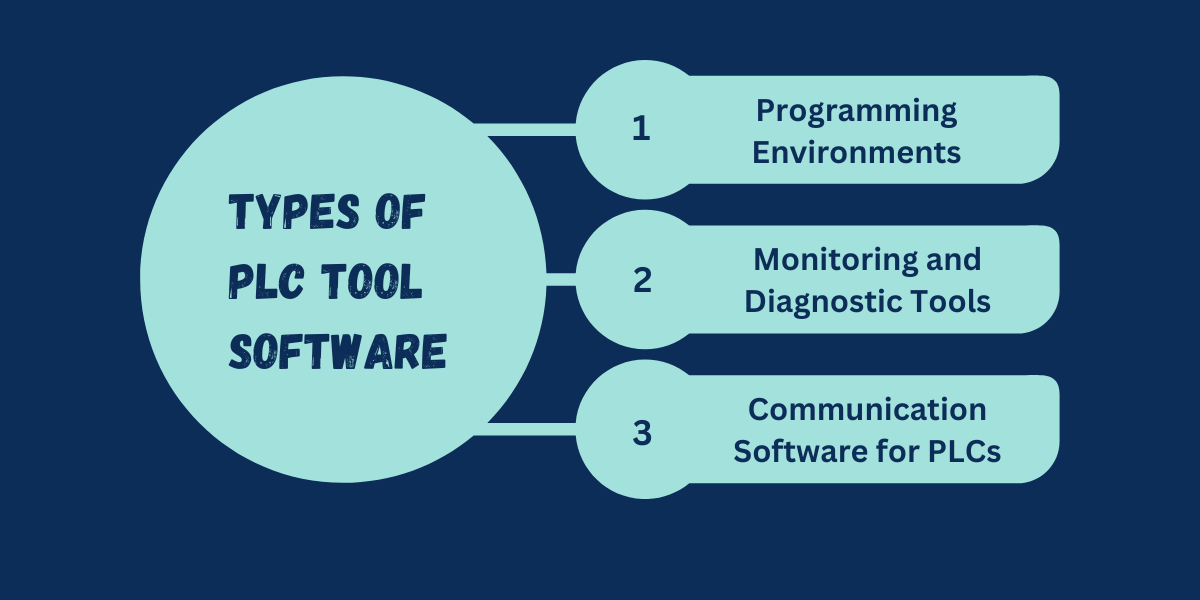

Types of PLC Tool Software

Programming Environments

PLC Tool Software includes diverse programming environments such as ladder logic, function block diagrams, and structured text, catering to different programming preferences and requirements of users.

Monitoring and Diagnostic Tools

Advanced PLC Tool Software offers monitoring tools for real-time data visualization, trend analysis, and performance tracking, enabling operators to monitor system status and diagnose issues effectively.

Communication Software for PLCs

Communication software integrated into PLC Tool Software facilitates seamless data exchange between PLCs, supervisory control systems, and other devices, ensuring smooth communication and coordination in industrial networks.

Choosing the Right PLC Tool Software

Factors to Consider

When selecting PLC Tool Software, factors like compatibility with existing systems, scalability, technical support, and cost should be evaluated to ensure the chosen software meets the specific needs of the automation project.

Popular PLC Software Options in the Market

Several renowned PLC Tool Software options are available in the market, including Siemens TIA Portal, Rockwell Automation Studio 5000, and Schneider Electric EcoStruxure Control Expert, each offering unique features and capabilities for diverse industrial applications.

Best Practices for Using PLC Tool Software

Efficient Programming

Adhering to structured programming practices, documenting code, and utilizing built-in libraries and functions are essential for efficient programming with PLC Tool Software, ensuring code readability, maintainability, and reusability.

Maintenance and Updates

Regular maintenance, software updates, and backups are crucial to ensure the optimal performance and security of PLC Tool Software. Following best practices for version control and system backups minimizes the risk of data loss and system downtime.

Future Trends in PLC Tool Software

Integration with IoT and Industry 4.0

The future of PLC Tool Software lies in its integration with Internet of Things (IoT) technologies and Industry 4.0 concepts, enabling smart manufacturing, predictive maintenance, and data-driven decision-making in industrial automation.

Predictive Maintenance Features

Advanced PLC Tool Software will incorporate predictive maintenance algorithms, machine learning capabilities, and predictive analytics to anticipate equipment failures, optimize maintenance schedules, and enhance overall equipment effectiveness in industrial settings.

Conclusion

In conclusion, PLC Tool Software is a cornerstone of industrial automation, offering a wide array of features, benefits, and applications that drive efficiency, productivity, and innovation in manufacturing and process industries.

Understanding the nuances of PLC Tool Software and embracing future trends is essential for staying competitive in the rapidly evolving landscape of automation technologies.