List of PLC Tool Software

Discover the best PLC tool software to enhance efficiency and reliability in industrial automation. Our comprehensive guide reviews top software options and offers insights on choosing the right tool for your needs.

In the ever-evolving world of industrial automation, Programmable Logic Controllers (PLCs) are the backbone of modern manufacturing and process control. These devices, which can automate complex industrial tasks with precision, rely heavily on specialized software tools for programming, monitoring, and maintenance.

The right PLC tool software can significantly enhance efficiency, reduce costs, and streamline operations. This blog post delves into the world of PLC tool software, providing a comprehensive list and insightful reviews of the top options available in the market.

Understanding PLC Tool Software

What is PLC Tool Software?

PLC Tool Software is a collection of applications and programs designed to create, test, and maintain the code that runs on Programmable Logic Controllers.

These tools are essential for configuring the hardware, writing and debugging programs, and ensuring that PLC operates as intended in various industrial environments.

Definition and Purpose of PLC Tool Software

The primary purpose of PLC tool software is to facilitate the programming and controlling of PLCs. This software includes environments for code writing, simulation tools for testing, and interfaces for monitoring and diagnostics.

It ensures that industrial processes run smoothly and efficiently by providing a reliable and user-friendly platform for engineers and technicians.

Types of Functions Performed by PLC Tool Software

PLC tool software performs several critical functions:

- Programming: Creating and editing the control logic that the PLC will execute.

- Simulation: Testing the control logic in a virtual environment before deployment.

- Monitoring: Observing the real-time operation of the PLC and the controlled process.

- Diagnostics: Identifying and troubleshooting issues within the PLC or the controlled system.

Benefits of Using PLC Tool Software

Efficiency Improvements in Programming and Monitoring Industrial Processes:

PLC tool software enhances efficiency by simplifying the programming process, reducing the time required to develop and deploy control logic. It also allows for real-time monitoring and adjustments, ensuring industrial processes are optimized and running smoothly.

Cost-Effectiveness and Time-Saving Advantages:

Investing in robust PLC tool software can lead to significant cost savings. These tools help maintain continuous production and reduce maintenance costs by minimizing errors and reducing downtime. Simulating and testing programs before implementation also saves time and resources.

Top PLC Tool Software in the Market

1. EcoStruxure Control Expert:

EcoStruxure Control Expert (formerly Unity Pro) is a comprehensive software solution from Schneider Electric. It offers advanced programming capabilities, powerful simulation tools, and a user-friendly interface, making it a popular choice for various industrial applications.

2. CODESYS:

CODESYS is an independent development environment for programming controller applications. Known for its flexibility and support for multiple PLC brands, CODESYS provides a versatile platform for industrial automation projects.

3. SILworx:

SILworx by HIMA is designed specifically for safety-related applications. It offers intuitive programming interfaces and robust diagnostic tools, ensuring high reliability and safety in industrial processes.

4. TwidoSuite:

TwidoSuite, also from Schneider Electric, is tailored for smaller PLC systems. It offers a straightforward programming environment and is ideal for simpler automation tasks and applications.

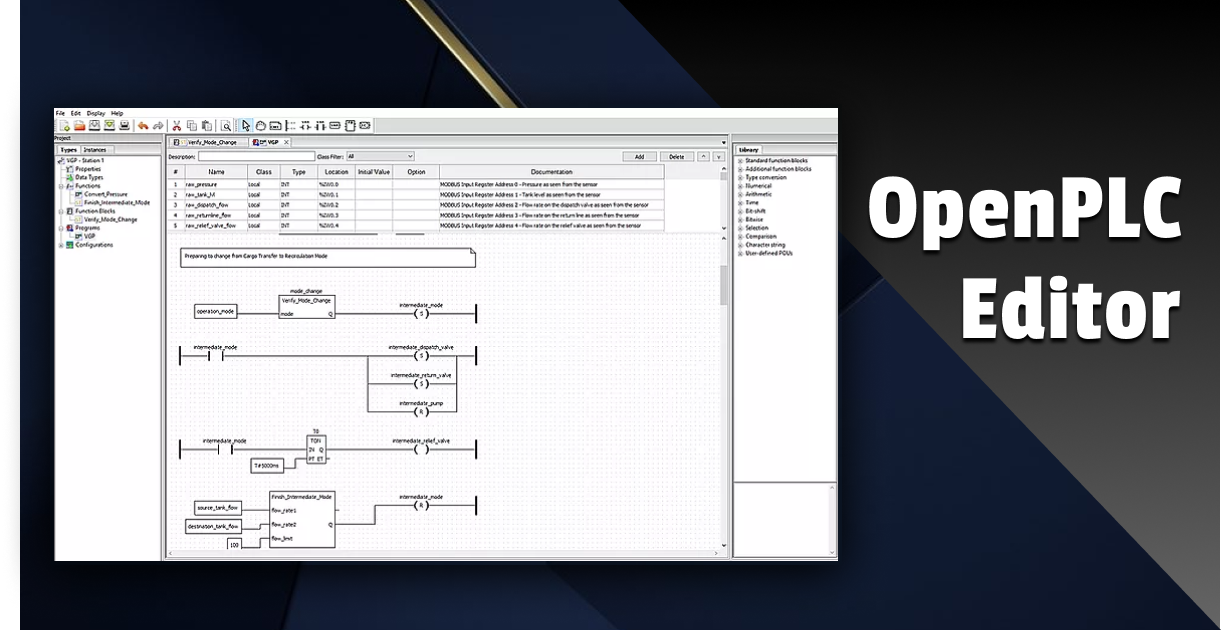

5. OpenPLC Editor:

OpenPLC Editor is an open-source tool that provides a cost-effective solution for PLC programming. It supports multiple programming languages and offers a flexible platform for developing custom control solutions.

6. RSLogix 500:

RSLogix 500 from Rockwell Automation is designed for Allen-Bradley PLCs. It provides a comprehensive programming environment, powerful diagnostic tools, and seamless integration with other Rockwell Automation products.

7. TIA Portal:

Siemens TIA Portal offers a unified engineering environment for automation projects. It supports a wide range of Siemens PLCs and provides advanced programming, simulation, and diagnostic capabilities.

8. ABB Automation Builder:

ABB Automation Builder is a versatile tool for programming and configuring ABB PLCs. It integrates seamlessly with other ABB products and offers robust features for industrial automation.

9. CX-Programmer:

CX-Programmer by Omron is a powerful programming tool for Omron PLCs. It offers an intuitive interface, comprehensive diagnostic tools, and support for various programming languages.

10. Siemens Industry Inc:

Siemens Industry Inc. offers a range of PLC tool software, including STEP 7 and WinCC. These tools provide advanced programming and monitoring capabilities, ensuring efficient and reliable industrial automation.

Factors to Consider When Choosing PLC Tool Software

1. Compatibility with PLC Hardware:

Importance of Selecting Software Compatible with the PLC Hardware in Use

Choosing software compatible with your PLC hardware is crucial for seamless integration and optimal performance. Ensure that the software supports the specific PLC models and brands used in your operations.

Considerations for Future Scalability and Upgrades

Consider the scalability of the software to accommodate future expansion and upgrades. Opt for solutions that offer flexibility and support for a wide range of PLCs and automation devices.

2. User Interface and Ease of Programming:

Evaluating the User-Friendliness of the Software Interface

A user-friendly interface simplifies programming and reduces the learning curve for engineers and technicians. Look for software with intuitive navigation, clear documentation, and helpful tutorials.

Availability of Programming Resources and Support

Access to comprehensive programming resources and support is essential for the effective use of PLC tool software. Check for available training materials, user communities, and technical support services.

3. Security and Data Integrity:

Ensuring Data Security and Integrity Within the Software

Data security and integrity are paramount in industrial automation. Choose software that offers robust security features, such as encryption and access controls, to protect sensitive data and ensure system reliability.

Features for Backup and Recovery in Case of System Failures

Backup and recovery features are critical for minimizing downtime and preventing data loss. Ensure the software includes automated backup capabilities and easy recovery options in case of system failures.

Conclusion:

PLC tool software is indispensable in the world of industrial automation, offering powerful features for programming, monitoring, and maintaining PLC systems.

By choosing the right tool, industries can enhance efficiency, reduce costs, and ensure the reliable operation of automated processes. As technology advances, the capabilities of PLC tool software will only expand, driving further innovations in automation and control.